Electrical and mechanical contractors give some advice about the process of installing transformers

The process of installing transformers requires a lot of technical factors and practical experience, which not all mechanical and electrical contractors are fully capable of.

A transformer is generally a product that integrates a lot of technical elements. The specifications of the machine must not only meet the electricity needs of the investor but also must meet the requirements of the transmission unit. The investor is the unit that buys the transformer but the choice of which machine and which manufacturer makes depends entirely on the criteria prescribed by the electricity unit. These criteria revolve around the purpose of ensuring national grid safety and the stability of the electricity transmission system in general. The investors themselves, with limited professional capacity, if it is right to choose the type of machine with the appropriate parameters to use, it is difficult to undertake the process of installing - connecting the grid. This fact has forced M&E contractors such as Galaxy M&E to act as an intermediary between the investor and the power unit. To help customers better understand the criteria of the installation process of the transformer, Galaxy Mechatronics will provide information related to the process of receiving, transporting and installing equipment with the following content:

| Voltage level (kV) | 35/0,4 | 15/0,4 - 22/0,4 | 63/0,4 - 10/0,4 |

| No-load loss Po (W) | 275 | 265 | 240 |

|

Load loss Pk (W) |

1150 | 1150 | 1150 |

| No-load current Io (%) | 2 | 2 | 2 |

|

Short-circuit voltage Un (%) |

4,5 | 4 | 4 |

| Size (mm) | 1160 x 680 x 1330 | 1020 x 590 x 1055 | 900 x 580 x 1030 |

| Oil (kg) | 190 | 132 | 122 |

| Weight (kg) | 680 | 530 | 505 |

Parameter of one of the 3-phase 2 voltage transformers.

1. Receiving transformer

All transformers, before being delivered to customers, must meet the standards of TCVN 6306. TCVN 6306 specifies the indicators P0, Pk, the ratio of voltage and phase difference, winding resistance, Insulation. Inside:

- P0: No-load loss and no-load current. The unit of calculation is Watt (W);

- Pk: Short-circuit loss and short-circuit voltage. The unit of calculation is Watt (W);

- Voltage ratio: It is the ratio between high voltage and low voltage (for distribution machines). Unit of calculation is%;

- Phase deviation (applied to 3-phase machines): Unit is %;

- Coil resistance: Including high voltage and low voltage. The unit of calculation is Ohm (Ω);

- Insulation resistance: Including test electrode resistance, resistance between high voltage and chassis, between low voltage and shell, between high and low voltage. The unit of calculation is Ohm (Ω).

Transformers delivered to customers must still have lead. Accessories on the device must be intact. The case has no peeling of paint, chipped, no oil slicks.

The transformer must be firmly bound on the truck floor.

2. Transporting and unloading transformers

- Transformers, when arranged on means of transport, must have appropriate distances between transformers or other goods on the same consignment. Equipment must be firmly tied on the truck floor. That, must ensure that the transport process does not cause impact, deformation, chipping, and prevent the loosening of the bolts;

- When transporting, there must be shielding equipment for transformers;

- The loading and unloading of transformers must use specialized lifting equipment, ensuring the weight of lifting equipment is consistent with the weight of the machine;

- The process of lifting and lowering the transformer must be gradual, gentle and always maintain the vertical position compared to the area where the transformers are installation, ensuring no chipping, damage or deformation of the equipment;

- In any case, absolutely not lift two or more transformers at the same time or lift transformers at the same time with other goods.

3. M&E contractor advises on how to install the transformer

3.1. Conditions for installing the transformer in Vietnam

- Individuals and organizations participating in the installation must have professional knowledge and understanding of transformers, and at the same time be trained in electrical safety;

- Before connecting the power cable to the transformer, ensure that all connecting cables are not live (including AC and DC);

- Ensure that before connecting to the grid, the technical specifications of the equipment are suitable and meet the regulations of EVN and the transmission units;

- The environment temperature when installing the transformer must be less than 40oC and greater than 5oC;

- The maximum height to install a transformer is under 1,000 m;

- Earthquake coefficient is less than 0.1;

- The wind speed in transformer installation environment must be less than 160 Km / h;

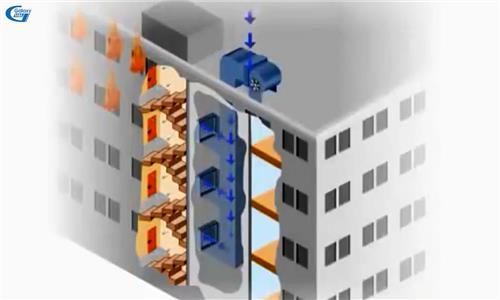

- The ground for installation of oil-cooled transformers must have oil-gathering pits and be fully equipped with fire and explosion prevention and fighting equipment;

- The ground for installation of the transformer must be well ventilated and away from heat sources;

- In places where there is a lot of dust and smoke, it is necessary to take measures to prevent and minimize dust and dirt acting on transformers.

Typical design of a 3-phase open-type transformer.

3.2. Check when installing the transformer

- The radiator fins and transformer housings are not deformed, peeling paint, casing surface damage and equipment installed on the transformer cover must be clean, free of dust and have no mold.

- The porcelain connection is not broken / batched, no oil flow on the porcelain / leg porcelain. Porcelain ensures cleanliness.

- Other equipment such as regulators, safety valves, oil level indicators, gas relays (if any), thermometers (if any) are in the correct position and ready to work. All equipment must be clean and free of oil spills;

- The earthing system must be installed in strict accordance with technical standards.

3.3. Note when installing the transformer

The air outlet of transformer room must have a system to prevent organisms outside the living environment from entering.

3.3.1. Installed in house

- The machine must have a door for cold air to enter (located in the lower part of the engine room) and hot air outlet (located at the top of the engine room). The vents must have a system to prevent organisms outside the living environment from entering (rats, birds, snakes ...);

- Hot air outlet should be calculated and constructed with an area large enough to support the cooling of the transformer;

- The distance between a transformer and a wall must be at least 0.5 m or more;

- The machine installation space must ensure easy access for equipment inspection and maintenance (for example adding oil, taking oil samples, observing oil levels, etc.);

- The transformer installation ground has an inclination of no more than 2 degrees.

3.3.2. Outdoor installation

- The transformer can be installed on a high platform or on a pole in accordance with the manufacturer's regulations and general technical standards of Vietnam;

- The installation position ensures balance and safety throughout the use and operation of equipment.

- Around the area where the machine is installed, there must be a barrier in accordance with the provisions of the State, ensuring safety during operation and if any incidents occur without causing damage to life and property around it.

It is necessary to strictly follow the inspection process of transformers, lines and load devices.

3.4. Check before turning on the power

- The changers and regulators (no-load regulators) must be in position corresponding to the applied voltage level;

- The distance between the two lightning protection heads with the 22 kV transformer is 10 cm and the 35 kV transformer is 14 cm;

- Oil level indicator in transformer (with oil cooler): White if oil quantity is sufficient and red if there is oil shortage. In case of oil shortage, it is necessary to contact the production unit, maintenance unit or installation unit.

- Cooling system: For large sized transformers over 3500 kVA, there is usually a valve separating the tank body and the radiator. Before turning the electricity off, the separation valve must be opened to allow coolant oil to flow between the chassis and the radiator;

- Some pressure protection devices (safety valve with closed-type transformer and explosive tube with open transformer), gas relays, thermometers must have no dust, grease.

- Test of insulation: When measuring insulation resistance, if the measured value is less than the parameter according to the machine profile, it is necessary to check the connecting conductors (including ground wire) with the transformer. Check to make sure these wires are completely isolated. If the wires are isolated but the resistance value is still smaller than the number written on the device, the people who turn the electricity off must stop and report to the manufacturing or distribution unit for remedial measures.

Above is the basic information related to the installation process of the transformer. Depending on the specific case, there will be specific criteria attached. All criteria, simple or complex, are aimed at ensuring electrical safety for businesses, efficient and optimal use of 1-phase transformers and 3-phase transformers.

Galaxy M&E

Other news