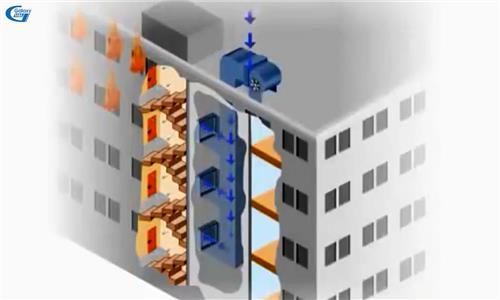

Pressure fan - The heart of wind system and fire protection system

The pressurized or turbocharged fan is the main component that creates the thrust of air flow in the ventilation system of construction works. Thanks to the high velocity of circulation, toxic fumes / gases from fires cannot invade the escape system.

Today, ventilation is always an indispensable component of electromechanical works. In addition to the task of regulating air, supporting air conditioning systems and ventilation systems, pressurized fans also have the function of participating in fire prevention system. Forced ventilation will not work without a pressurized fan.

There are two commonly used types of pressurized fans, centrifugal blowers and axial pressure fans.

1. What is a pressurized fan?

The pressurized fan simply means that the device generates an air flow and propulsion speed suitable for the intended use. This airflow is taken through the air outlet, through the throttle unit, and the duct inside or outside the building.

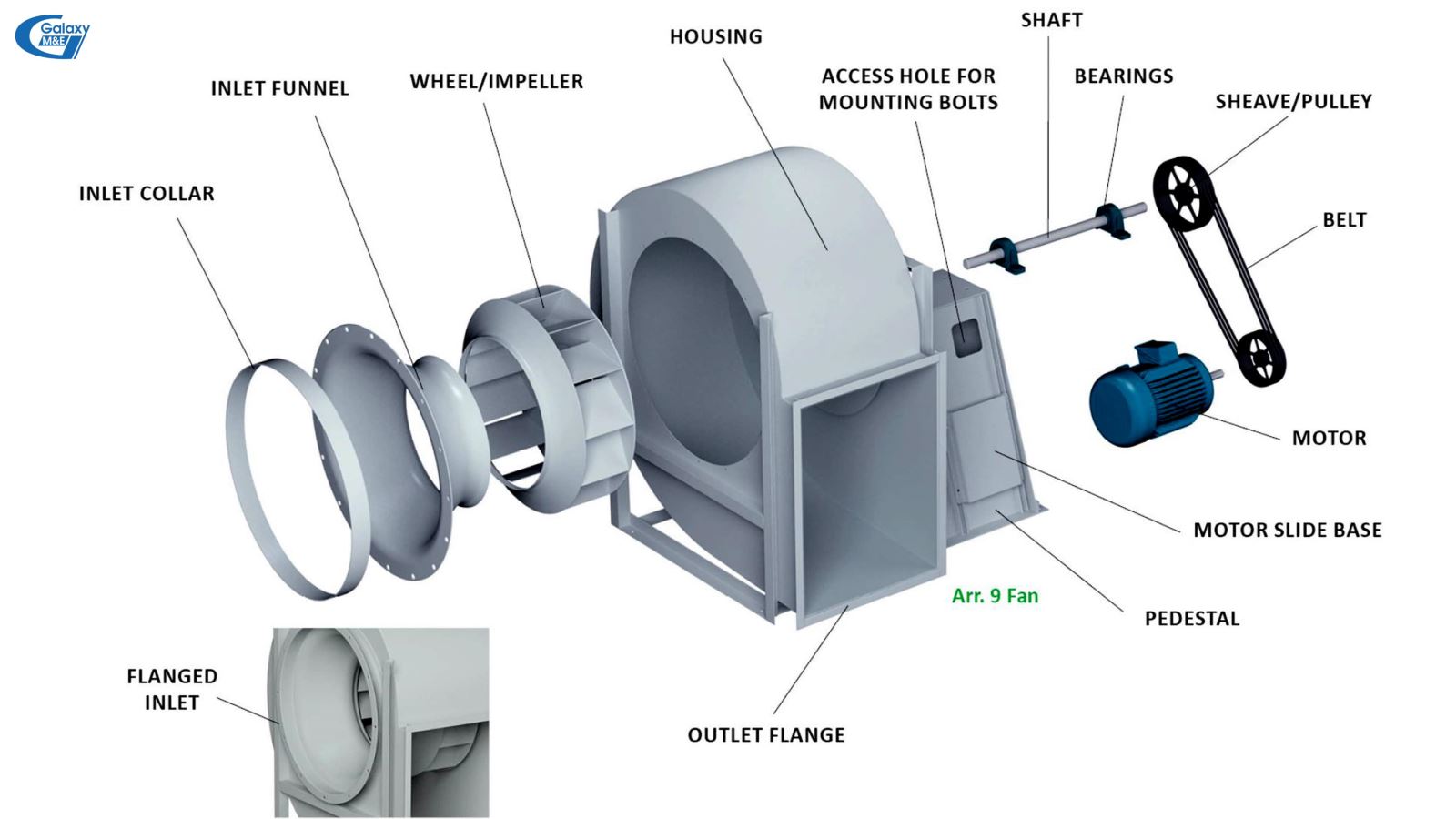

In terms of structure, pressurized fans include: Motors, propellers, control systems, air ducts, flow control devices, and air filtration devices. In order to distinguish between pressurized fans and compressors, the American Society of Mechanical Engineers uses a pressure-to-suction pressure ratio to distinguish pressurized fans and compressors.

The pressurized fan has a pressure-to-suction ratio of 1.11, increasing the pressure to 1136 mm WG (11,1372 kPa, respectively). Air compressors have a ratio of push pressure to suction pressure from 1.11 to 1.2, increasing pressure from 1136 to 2066 mmWG (equivalent from 11,1372 to 20,2549 kPa).

2. Types of pressurized fans

There are two main types of commonly used pressurized fans, centrifugal pressure fans and axial pressure fans.

Design of centrifugal pressurized fans.

2.1. Centrifugal blower fans

Centrifugal blower fans have the same shape as centrifugal pumps. The impeller centrifugal fan is driven by gears and rotates at a speed of 15,000 rpm. Centrifugal pressure fans are divided into 2 types, multi-level high-pressure type and single-stage high-pressure type. With the multi-stage high pressure type, the air is accelerated as it passes through each impeller. With single-stage high-pressure type, the air does not rotate much, so it creates a higher pressure.

Although centrifugal pressure regulators are divided into 2 types as above, if considered carefully, the performance actually depends on the structure of each type of impeller.

Centrifugal fans with radial blades:

- Suitable for high static pressure (approximately 13.72 mPa);

- Simple design, suitable for specialized equipment;

- Can operate at low flow without high vibration;

- There is a gap between switch gears and a large fan cover, suitable for the air containing solid dust (wood chips, metal filings).

Centrifugal fans with forward curved blades:

- Can move large gas flow with low pressure;

- Low stability, suitable for ventilation;

- The disadvantage of this type is the relatively low energy efficiency (from 55 to 65%).

The impeller centrifugal fan tilts back:

- This type can operate with variable static pressure without overloading the engine;

- Suitable when the system operates at high and unstable gas flow;

- Suitable for forced ventilation in office buildings, apartments, hotel complexes, commercial centers but not suitable for industrial environments with a lot of dirt.

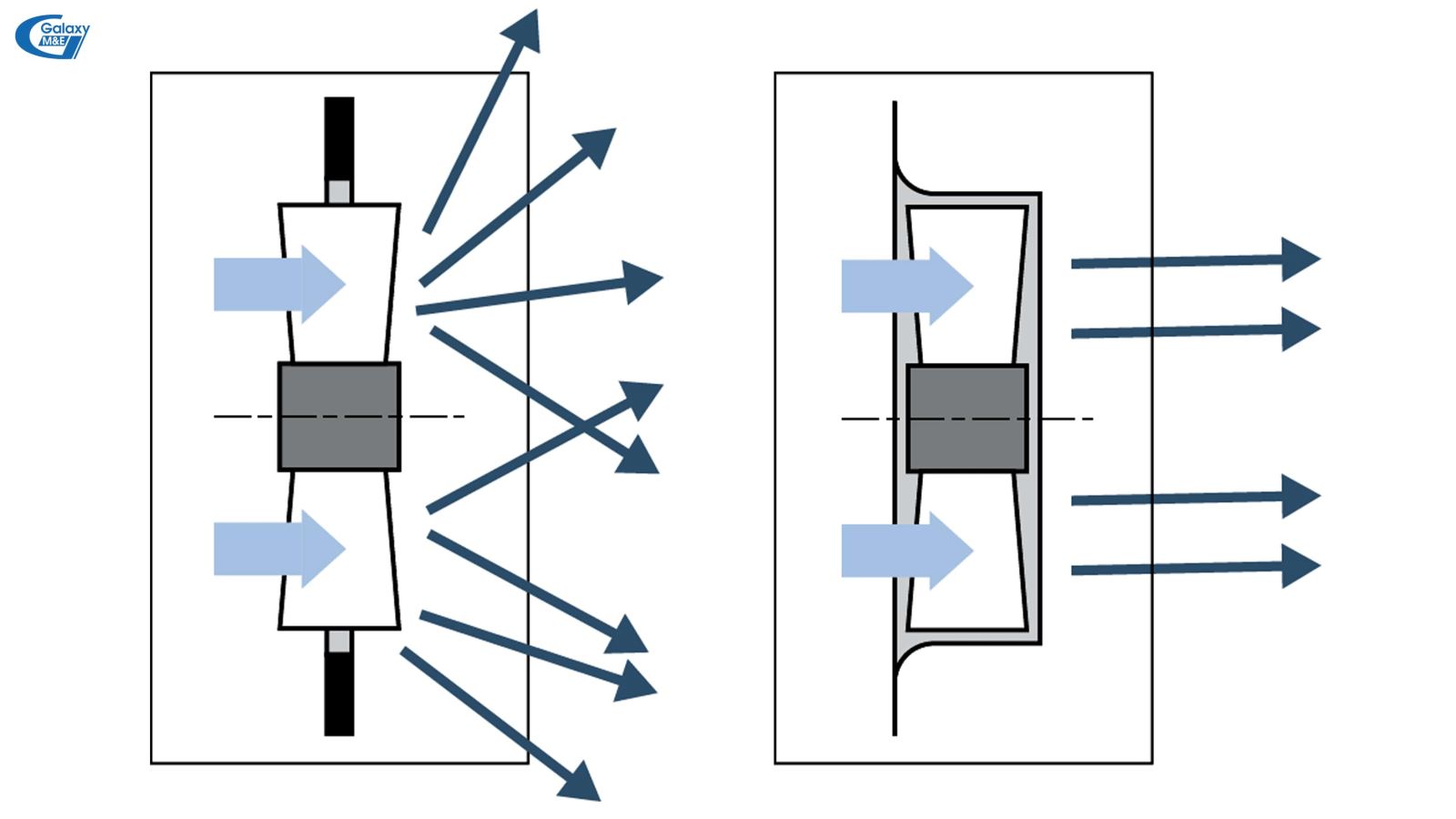

Principle of operation to the axial pressure fan.

2.2. Axial pressure fans

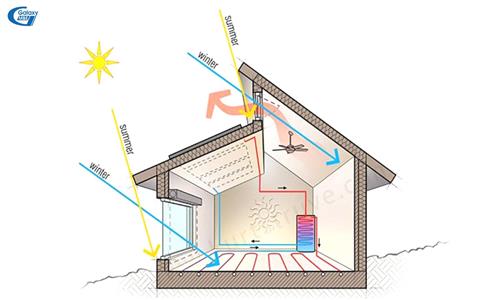

Axial pressure fans move the air flow along the rotating axis of the fan. There are two types of axial pressure regulators that are normally used for ventilation, which is the axial and ducted.

Axial pressure-driven fans:

- Create a higher flow rate when at low pressure;

- Not suitable to become stair pressurized systems;

- Can create counter-current, often applied to ventilation systems on rooftops.

Tubular pressure regulating fan:

- Quickly increased to the standard speed, and suitable for ventilation;

- Relatively high cost;

- Energy efficiency is approximately 65%.

Regular maintenance and cleaning of the ventilation system is a way to increase the performance of the pressurized fan.

3. Measures to increase the working efficiency of pressurized fans in ventilation systems and fire protection systems

In order to improve working efficiency, electromechanical experts must understand the functions of each device in the system. If the pressurized fan is too large compared to the ventilation system, it can create noise, waste energy, and reduce the equipments life expectancy. In addition, when selecting and installing pressurized fans suitable for system characteristics, to maintain and improve working efficiency, it is necessary to perform the following contents simultaneously:

- Use round, smooth air pipes to get air in;

- Minimize obstructions in the air intake and exhaust element of the rotor;

- Regularly clean the dust filter, fan filter;

- Remove unnecessary gears;

- Use stepless speed controller for variable fan loads;

- Eliminate leaks in ventilation and air ducts;

- Operating fans near the maximum efficiency level;

- Reduce transmission losses by using flat or trapezoidal belts;

- Regularly check the tension of the transmission belt;

- Regularly check the vibration to predict the damage due to bearings, unbalance, unstable position;

Selecting the type of pressurized fan depends entirely on the characteristics of the electromechanical works. For each project, the mechanical and electrical units will consult, design ventilation systems, fire protection units and select compatible pressure fans. In the face of requirements in safety, prevention and handling of fire incidents, the design and construction of staircase and ventilation systems in general, consultancy and fan installation, the pressurization in particular must necessarily be calculated based on the synchronization of the equipment and the structure of the building. If people have no good skills, and only work based on the feelings, the party who suffer from the problems will be the investor.

Galaxy M&E

Other news