Electrical leakage and notice needed | Galaxy M&E

During the course of using electricity, have you ever felt that your hands were numb? This is a sign of a cool leak, leakage of electricity, and is potentially life threatening.

In the electromechanical industry, leakage current is a physical phenomenon, caused by redundancy in the consumption of electricity.

1. What is electrical leakage?

Electrical leakage often occurs with equipment, machinery, which are outdated, or the earthing system does not meet the standards. In the electromechanical industry, leakage current is a physical phenomenon, caused by redundancy in the consumption of electricity or insecure insulation systems. Leakage currents not only cause energy loss, and reduce efficiency but also creates a risk electrical accidents to occur.

2. Causes of electrical leakage

The first cause comes from the age of power consumption equipment. Every device has a certain lifespan. The electrical conductors of the device undergo continuous working time, the heat generated during the work makes the mechanical and physical properties change, leading to the durability and the conductivity to also change. The aging phenomenon of the device takes place not only from the inside but also with the outer shell. The insulating coating (metal case) is gradually worn, peeling off, combined with the insulation of the aging conductor, creating a gap for the excess current to flow to the outside surface.

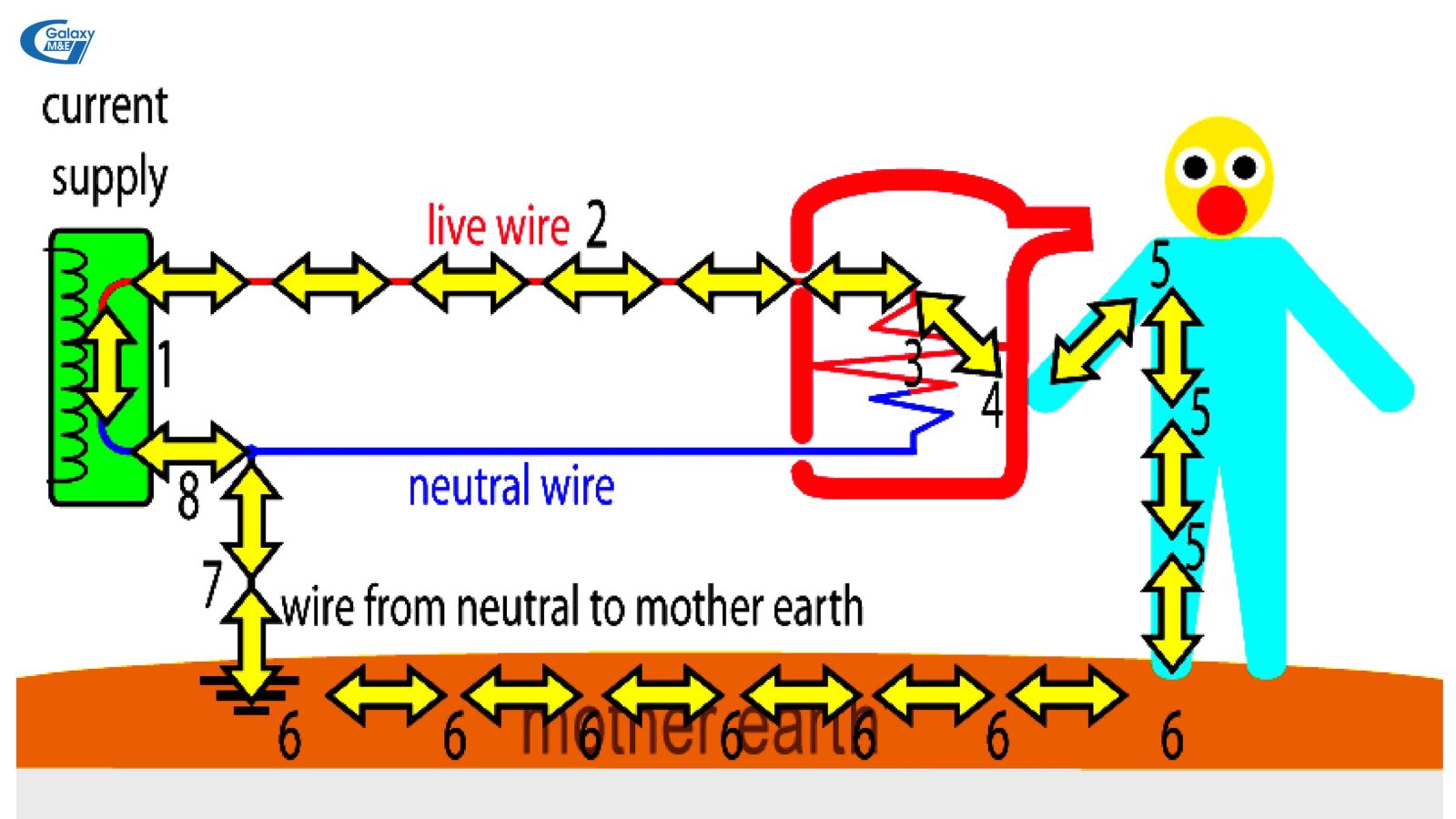

The second cause is from the environment. When the device is outdated, combined with moist air and metal dust, the resistance around the device decreases, increasing the risk of leakage. Especially if the user is wet (body/feet) and has direct contact with the ground, the risk of electric shock increases.

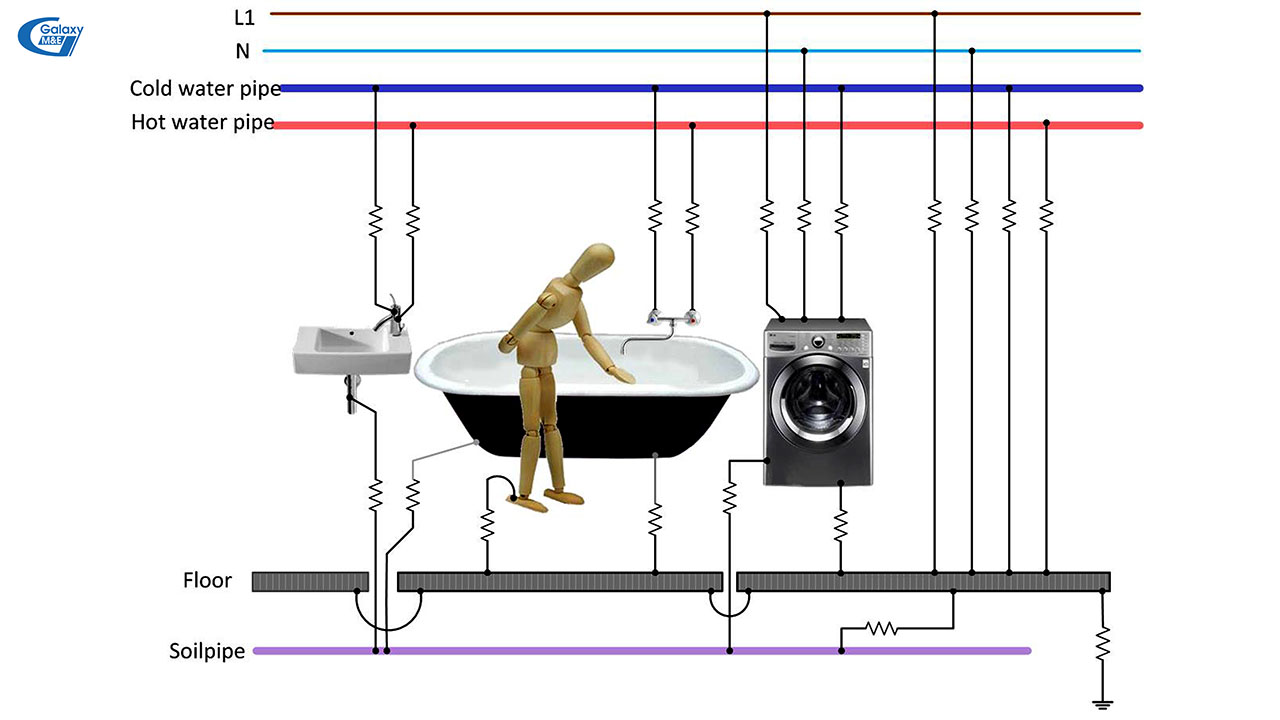

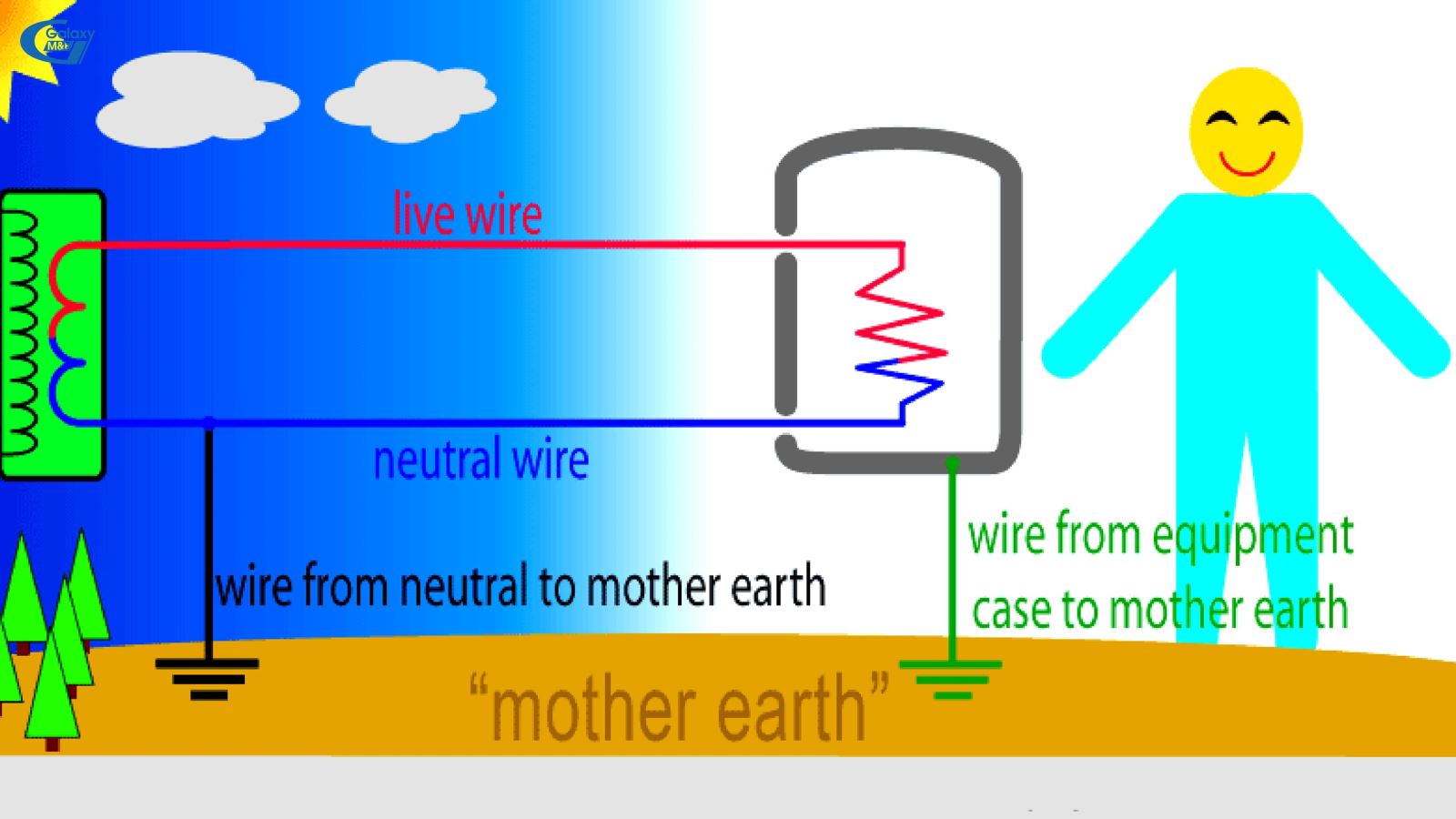

The third reason is that the earthing system is not ensured. Grounding works create paths of excess current (if generated) during use. If the earthing system is not up to standard or degraded, it creates a risk for labor and daily life. By standard, the resistivity of ground wire must be less than 4 Ohm. At this resistivity, the earthing wire will ensure the role of leakage current instead of propagating to the user. The earthing system has strict technical requirements and only mechanical and electrical specialists can design and execute it to ensure safe operation of electrical equipment and systems.

Leakage can occur anywhere, anytime if there are no effective precautions.

3. Signs of cool openings, leakage

3.1. With home electric system

One sign is when the circuit breaker is switched off. The reason for the circuit breaker jump is due to the voltage difference caused by leakage current.

In the case of a home electrical system without a circuit breaker against shock, it is more difficult to detect leakage current. Signs of electrical leakage occur by the sensation of the body when exposed to leakage current. In dry conditions, at a voltage below 36 Volt, the human body is not in danger. In humid environments, a voltage of only 6 Volt can be fatal. Therefore, in the process of using electrical equipment, if the body feels numbness or convulsions, it is necessary to immediately cut off the circuit breaker or circuit breaker, then contact a qualified person to inspect and fix the leakage/electricity.

With regular plug-in devices, such as televisions, refrigerators, if you smell anything or the devices stops working, instead of trying to reboot, the family should call someone with electromechanical expertise to check. Calling for people with special expertise is necessary for families without earthing systems. The range of electric shock doesn’t only happen to the equipment in use but also has the potential to spread fire. The search and rectification of the short-circuit location should be conducted as soon as possible to ensure maximum safety for users.

3.2. With industrial electrical systems

Currently there are many units advertising, selling leakage detection devices, but these devices are essentially ammeters, ohmmeters or multimeters. Leakage current detection requires a special device. This device has a high price and requires intensive knowledge in mechanics, so not all facilities are capable of investing and operating.

Instead of investing in specialized inspection equipment, industrial establishments often equip standard earthing systems, suitable for electromechanical systems. When there is a leakage current, thanks to the earthing system, the leakage current will cause a short circuit that stops the device from operating, thereby cutting off the power source and creating a safe environment for workers.

The earthing system will help minimize leakage currents.

4. How to prevent cool air leakage/electric leakage

4.1. Prevent cool openings, and leakage at home

With the household’s electricity system, during the construction of the house or before entering, the family should adopt an experienced person to design, execute and check the earthing system. Once the home network has an earthing system, following the manufacturer's instructions for electrical appliances, this will eliminate the risk of electrical leakage. Noteworthy, with three-pin plugs Vietnamese people often have the habit of breaking the middle pin to plug it in more easily. The removal of this third pin accidentally cuts off the leakage path (if any). If the device leaks, the voltage will spread to the surrounding shell or surroundings creating a hazard to the user.

The characteristics of household electrical appliances are often small in capacity, so the investment and installation of shock-proof circuit breaker is feasible and extremely necessary. Today, many manufacturers of home appliances have actively equipped ELCB for customers to prevent electrical leakage during use.

4.2. Prevent electricity leaks in industrial facilities

For industrial production facilities, inspection and maintenance of equipment is always a necessary requirement. The periodic inspection helps to detect damage on equipment and electrical systems. In addition, as mentioned in Section 3.2, the earthing system is always mandatory not only for industrial facilities but also for offices. The earthing system should be designed to standards and installed by qualified personnel.

Theoretically, there are two types of earthing systems. Independent earthing system and repeated earthing system. The common point of 2 earthing systems is that there are always earthing poles and wires. Grounding piles usually have V-shape or large diameter iron pipes to increase the area of contact with the soil. The minimum depth of a grounding pole calculated from the foundation must be 1.2 m or more. In engineering, the number of earthing piles grounded for each workshop or equipment (depending on the characteristics of each industrial facility) is optimal at 9 piles. 9 stakes are divided into 3 groups, each group of 3 stakes driven into the ground in a triangle. The grounding conductor has one end attached to the device cover, the other is connected to 3 groups of piles. After connecting conductors and grounding piles, the construction party needs to bury the pile heads and welding points between the wires and the piles.

The repeated earthing system is different from the independent earthing system. Instead of a wire connected to the case, the earthing pole will be connected to the neutral wire of a 3-phase electrical network. In the event of a leakage, the excess current will be propagated simultaneously to the grounding system and the neutral wire, so the time of current dispersion is shortened. However, the repeated earthing system is almost not used. This is due to the fact that phase-shifting phenomena are common and unavoidable. When the phase command, the voltage difference will be transmitted across the neutral wire, from the neutral wire transmitted back to the device causing a fire.

Compliance with electrical safety regulations is mandatory for every individual involved

in the use of electricity.

5. Safety measures to help prevent electrical leakage

In addition to the grounding system, the use of anti-shock circuit breaker, the maintenance of the equipment in the best operating state, ensuring a clean living and working environment, avoiding moisture and metal dust, compliance with the regulations on electricity safety is mandatory for every individual involved.

For individual households, especially families with young children, following the recommendations of electromechanical experts are essential to ensure safety and prevent the risk of electrical accidents from occurring.

For production facilities, the study and compliance with electricity safety regulations not only ensure a safe working environment but also contribute to increasing the efficiency of production.

With 16 years of experience in the field of mechatronics, Galaxy M&E is ready to consult, design and provide complete solutions for medium and low voltage electrical networks in industrial production facilities, office building, hotels, and resorts. In the spirit of considering the Safety - Stability - Modernity of the works already under construction as the foundation for development, Galaxy M&E is confident to become the No. 1 choice of M&E works, which is the place to CREATE VALUES for today and for tomorrow.

Galaxy M&E

Other news