Effective prevention equipment for M&E works

Galaxy M&E is ready to advise and help customers solve problems related to the construction, maintenance and operation of electromechanical systems in general, and give effective information and knowledge for electromechanical works in particular.

Ensure the smooth operation of the electrical systems, in addition to the design, construction, operations, maintenance issues, and preventive support measures are also a requirement. A generator is a necessary device for buildings that affect national security, hospitals, buildings, and office complexes. When the power grid has a problem / interruption of transmission, the generator will supply power. Imagine, in a surgery, if the electricity is lost how would the operating equipment work, how would a patient's life be affected?

Generators are essential in construction projects. Not every individual or organization knows how to choose a generator, what its capacity is, and how much it costs. In order to have explicit answers to these issues, individuals / organizations need basic knowledge about the structure, operation and classification of generators. With many years of experience in designing, constructing and maintaining the electrical system, with the following content, Galaxy M&E will answer in detail the three issues mentioned above.

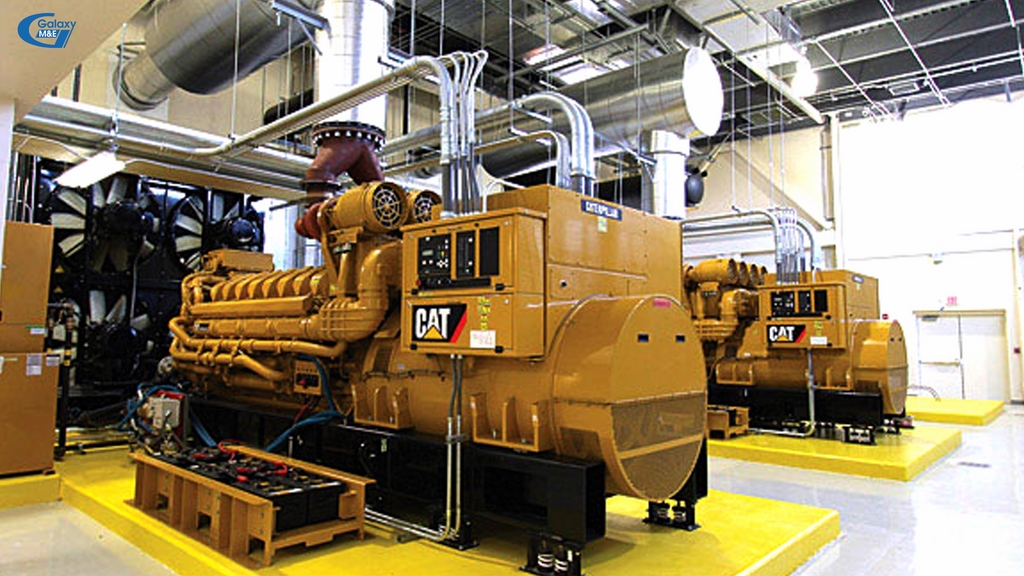

North Carolinas emergency generator system in the USA.

1. Overview of generators - Effective prevention equipment for electromechanical works

Generators consist of main parts of that of an engine, a transmitter, a control panel, a sound enclosure and a chassis. The engine uses motion to turn mechanical energy into electricity. The frame and the platform helps keep the machine running smoothly. The transmitter converts power into electricity. Control panel is used to display detailed parameters related to the engine, generator, frequency, revs, fuel consumption, temperature ...

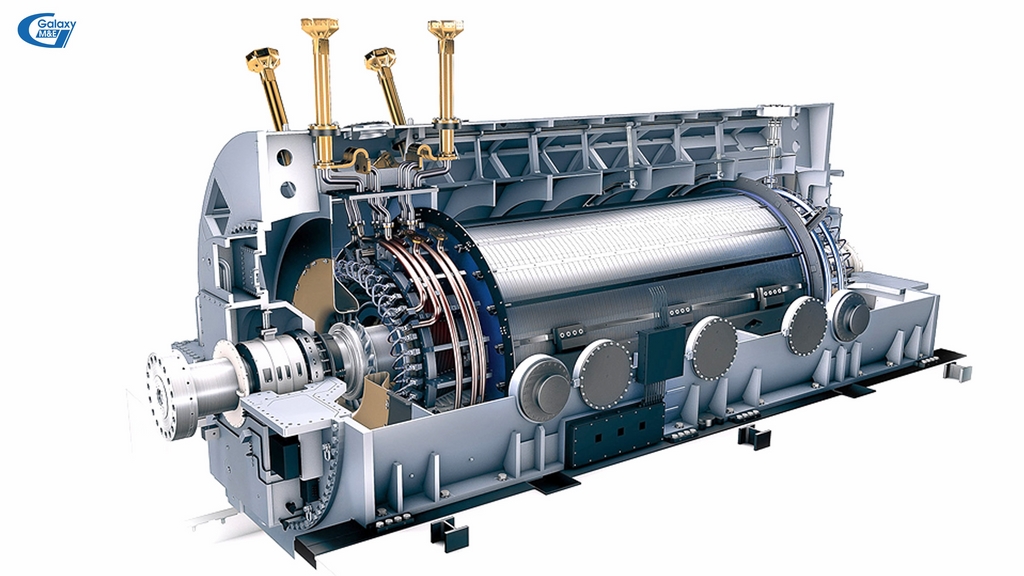

2. Detailed structure of the synchronous generator

The structure of a generator motor.

2.1. Engine

The engine of a generator either consumes diesel or gasoline. The engine helps to convert mechanical energy from petrol and oil into a synchronous rotating generator moment, converting mechanical energy into electricity based on electromagnetic induction.

The engine consists of two main parts: the rotor and the stator.

- Rotating rotor: is the sensor (creating a magnetic field) in the form of electromagnets. DC power source rectifier and external magnetic supply (battery or rectifier from the generator source, etc.). Rotor has the function of converting direct current into alternating current. Rotor generates a larger alternating current around the stator’s coil.

- Stator at rest is an armature consisting of 3 separate coils, exactly the same, wrapped on 3 iron cores placed at different intervals of 1200 on a circle.

An auxiliary fuel tank layout for generators.

2.2. The fuel tank for generators

Generators use many different types of input fuels such as diesel, gasoline, propane (liquid or gas) and natural gasses. Small engines often run on gasoline, while larger engines run diesel oil, liquid propane, propane gas, or natural gas.

The generator's fuel tank can operate for 6 to 8 hours depending on the type. For small generators, the fuel tank is part of the generator base or is it mounted on the generators frame. For commercial generators, an external fuel tank may be required.

Common features of the fuel system include the following:

- Connecting pipe from fuel tank to engine: the supply line leads fuel in and out the engine.

- Fuel tank ventilation pipe: The fuel tanks have a ventilation pipe to prevent an increase in pressure or vacuum during the pumping and drainage of the tank. When filling the fuel tank one should ensure dry contact between the auxiliary nozzle and the fuel tank to prevent sparks causing a fire;

+ Connecting the fuel tank to the sewer pipes: This is the step to ensure that there is no spillage of liquid on the generator.

+ Fuel pump: Fuel transferred from the main tank (at full capacity is especially important to commercial organizations) into another tank during the day. Conventional fuel pumps are powered by electricity.

- Fuel filter- this separates water and foreign objects in the liquid fuel to protect other components of the generator from corrosion and clogging.

- Nozzles: This sprays mist created by liquid fuel into the engine combustion chamber.

2.3. Cooling system

The generator needs a cooling and ventilation system to recover the heat generated during operation.

Untreated water / clean water is sometimes used as a coolant for generators. In addition to water, Hydrogen is a good heat absorbing material, used to cool generators' stator coils. Hydrogen removes the heat from the generator and passes it through a heat exchanger leading into a secondary cooling circuit, that contains mineral water (used as a coolant). This is why generators are so large in size.

The cooling system and raw water pump need to be washed after every 600 hours of operation. The heat exchanger should be cleaned after every 2,400 hours of operation. The generator should be placed in an open, well-ventilated area to facilitate better cooling.

2.4. Lubrication systems

When operating, the internal parts of the generator need to be lubricated to ensure its longevity and limit noise generated during use. The generator motor is lubricated with oil and stored in a pump. The testing of lubrication oil level should be performed every 8 hours that the generator operations for. In addition to preventing lubricant leakage, every 500 hours of operation, the generators’ lubricating oil needs to be changed.

2.5. Other parts

- Voltage stabilizer converts AC voltage into DC direct current. This direct current is gathered in the stator secondary coil, called the excitation coil.

- The excitation coil converts DC current to AC current. The stimulation coils function is similar to that of the main stator which generates small alternating current. The excitation coils are connected to units called rotary rectifiers.

+ Rotating rectifier: Convert direct current into alternating current. Rectifier alternating current is generated by the excitation coil and is converted it into direct current.

2 to 4 kW power generators are suitable for small offices or household.

3. Classification of generators

Depending on the power demand, the environment, the features of the generator, there are 5 ways to classify the generator:

3.1. Classification according to fuel used by engine:

- Gasoline generators have low capacity and is generally used for households, shops, transaction offices ...

- Diesel generator have a wide power range to meet all power consumption needs.

- Generator running biogas: Biogas is a gaseous fuel generated from animal manure and fermented organic substances. Biogas generators are useful for households and industrial units.

3.2. Classification according to the engine cylinder layout:

Generators have 1 to 16 cylinders. Depending on the number of cylinders, manufacturers have different arrangements, different performance and cost.

- V engine generator: The highest is V16. The cost of these are generally high.

- Engine generator I (L): The highest is 6 cylinders;

- In-line engine generators;

- Horizontal symmetrical engine generator ...

3.3. Classification based on the type of cooling:

- Wind-cooled generators are usually small, low-power machines use for small families/offices.

- Water/gas cooled generators with large capacity are often used for buildings, hospitals ...

3.4. Classification of generators:

According to the output voltage:

- Single-phase generators (110/220 V - AC): Power of under 10 kVA;

- 3-phase generators (230/400 V - AC): Power range of 10 kVA or more.

By frequency:

- 50 Hz generator: Are mainly found in Vietnam.

- Generator 60 Hz: Are found in United States, Japan and European countries.

3.5. Classification by adjusting the output voltage:

- Generator with AVR: Automatically balances the output voltage.

- Generator without AVR: Output voltage will vary.

4. The price of a generator

In addition to factors such as capacity, features, technology, brand, origin, the price of a generator usually depends on three factors as follows:

Rotation speed:

- Generator speed 3000 rpm: Usually small capacity and low cost;

- Generator speed 1500 rpm: Has more capacity and is higher in price.

Adjust the engine speed:

- Generators adjust engine speed with low cost motors;

- Generators that adjust engine speed electronically have a higher price.

A soundproof form for the generator

Noise-proof housing:

- Generators with noise-proof housing: Usually with an S in the model symbol, are heavier, louder and more expensive;

- Generator without noise-proof cover: Lower cost and may affect the users health.

Above are the basic contents related to choosing a generator that suits the needs and investment costs. In addition to the information mentioned above, referencing consultancy, electromechanical construction is a way to ensure that the investor has the right and appropriate decision. The advice may come from the generator distribution units but the understanding and the ability to synchronize the generator with consumer devices are not always possible for all units.

With more than 15 years of experience in designing and constructing M&E works for investors from Japan, the United States, state-owned units, Galaxy M&E is ready to consult and help customers to solving problems related to construction, maintenance and operation of electromechanical systems in general and electromechanical devices in particular.

Galaxy M&E