5 steps to implement during mechanical & electrical construction | galaxy m&e

This procedure is generally applied to the electrical construction of buildings, hotels or other civil engineering constructions.

As a unit specializing in designing and constructing and mechatronic systems, Galaxy M&E would like to send readers an introduction about the process of conducting electrical system works. This procedure is generally applied to the electrical construction of buildings, hotels or other civil engineering constructions.

1. Overview of the electricity system in construction

In construction works / electromechanical construction, electrical systems can account for 30-50% of the total workload. There are power projects that can account for up to 80% of the total construction and installation volume. Electrical systems in buildings are usually divided into two parts: heavy power and light electricity.

Heavy power system:

- Transformer station - Capacitor for capacity compensation;

- ATS - Generator - UPS;

- TrunKing - Tray cable - ladder cable;

- Electrodynamic cabinets - Control;

- Wires - CB;

- Water pumps - Water pipes;

- Lighting systems;

- Anti-lightning system.

Simple power system:

- Telecommunication infrastructure system of the building;

- Computer network cable system, telephone cable, telephone exchange;

- CATV central television system;

- CCTV security camera system;

- Door phone system - Unlock and unlock with magnetic cards;

- Public broadcasting system;

- Vehicle access control system;

- Building management system.

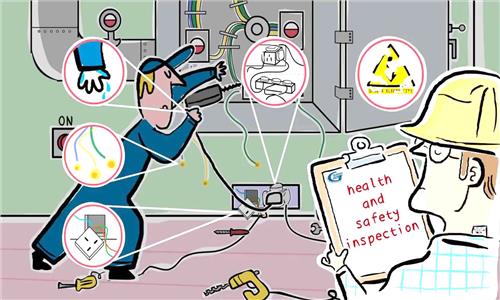

2. Organization before construction, installation of electricity construction

As mentioned above, the electricity system can be interpreted as all the work done in order to bring electricity to devices and consume electricity. In order for the process of construction, electrical installation works must be safely done and on schedule to ensure the overall quality of the whole project.

5 steps to follows:

- Installation of protective pipes;

- Installation of electrical cables;

- Installation of electrical cabinets, electrical panels;

- Installation of electrical equipment;

- The work of inspection, acceptance, testing, operation.

Protective tubes in the electrical system of the United States

2.1. Install protective pipe

The purpose of installing the protective pipes is to ensure the best condition for the cable system, underground pipes, air-conditioner drainage pipes. Protective tubes used in construction can be flexible plastic, stainless steel, and can be easily bent. Locations of pipes may be buried underground in concrete walls and floors. The positions with technical floors, pipes going on the technical floor are placed.

Pipes placed in concrete floors are constructed after the construction worker has finished the iron floor layer. In the position where there is only one layer of iron floor, plastic pipes are placed on that layer of iron, and in places with two layers of iron, plastic pipes are placed between two layers of iron. At the junction, the pipes are bent by springs with a radius of 6 - 9 times the diameter of the pipe. Galaxy M&E doesn’t use the connector in these positions, which affects the wire pulling due to the extreme angle. Every turn from 3 branches or more Galaxy M&E uses boxes to facilitate wire pulling and checking. All the ends of the pipe with wires are sealed to prevent foreign matter from causing harder maintenance in the future. When underground pipes are placed in locations where pipe cuts and restricts connection, all heads will be cut and smoothed, this is to prevent wires from scratching when threading.

The pipes going through the underground walls are constructed after the first 5 days of wall construction to ensure the wall is hard enough not to crack. The distance between two pipe connectors shall not be shorter than 50 mm. Pipes buried underground in concrete walls or ceilings are always fixed with cement or concrete.

Tubes go in the wall vertically or in parallel. At the end of the tube is where the switch box, socket, light box is located. Light boxes in concrete floors will be stuffed with paper or styrofoam and wrapped with duct tape before fixing to the formwork to prevent concrete from entering. The inlet pipes are bent so that it is 7 mm from the formwork layer to avoid later cracking.

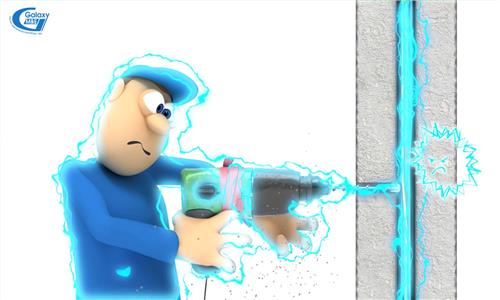

The pipe on the technical floor or in technical boxes are fixed and the distance between the clamps is not greater than 1200 mm. Screws and rawlplugs will be used to attach pipe clamps and holes drilled by an electric drill.

Light boxes, switch box boxes are placed at a height that is designed with water scales to accurately determine the level and use nivo ruler to ensure the boxes are fixed after installation.

The wires and cables are separated according to the color of the wire. Phase wires: Blue, red, yellow. Neutral wire: Black. Grounding wire: Green / yellow.

2.2. Installation of power cables

The construction of electrical wires and cables should be carried out after the installation process only when the protective pipe system is completed. The wiring is done by a team of experienced electromechanical workers, ensuring the wiring is simple to install, and is convenient for repairing and replacement. The number of wires in the pipe is calculated so that it occupies no more than 40% of the pipe cross-section which creates better conditions for replacement. The wires and cables are separated according to the color of the wire. Phase wires: Blue, red, yellow. Neutral wire: Black. Grounding wire: Green / yellow. The wires are segmented in accordance with the design drawings. The ends of the wires will be marked in the order of the electrical distribution cabinet to facilitate zoning if something goes wrong.

Galaxy M&E only performs wiring at junction boxes, switch boxes, outlet boxes and light boxes. This minimizes short-circuit breakdowns due to unsecured joints and makes the repairing process and inspection easier. The wire and cable ends use cables to connect the device. The diameter of a cable end is suitable for wire. The joints and wires ensure absolute insulation throughout the system. The connectors and unconnected lines do not overlap on cross sections (must be staggered). When installing, the distance of the line is placed from the ceiling top to the edge of the door, the edge of the column is to not entangled when installing other items. After installation of the wiring system, Galaxy Electrical and Mechanical will test the lines insulation: Phase - phase, phase - earth, phase - neutral, neutral - earth.

Underground cable culverts are placed at a depth of at least 800 mm, at cross-roads or places with traffic the cable culverts will be threaded through PVC-protected concrete pipes. Make sure this is less than or equal to 40% to prevent heat dissipation of the wire. Galaxy M&E always uses long cables for all underground construction projects. During the cable construction and installation process, if a faulty cable is detected, a sharp object can damage the protective layer, if the cable is faulty which is produced by the manufacturer (such as bulging, heterogeneous), Galaxy M&E resolutely suspends and will immediately notify the investor, supervise the work to give timely measures, ensure quality and safety for the whole project.

Galaxy M&E always has the equipment installed in the electrical cabinet immediately after winning the bid to ensure the work schedule.

2.3. Installing electrical cabinets, electrical panels

Electrical cabinets with wall mounted type pedestals: The installation of these cabinets will be combined with construction work. Iron bars and rawlplugs will be positioned before finishing the wall.

In the cabinets, the nameplates of the branches will be attached to facilitate later inspection and operation. The equipment in the cabinet is installed, connected, calibrated by senior mechanical and electrical engineers, which is tested by specialized equipment. Sized drawings and details of the equipment in the cabinet will be provided to the investor and supervision consultants before proceeding with the production and installation of cabinets. The switchboard will be manufactured and installed in accordance with the bidding documents and IEC standards.

Galaxy M&E always has the equipment installed in the electrical cabinet immediately after winning the bid to ensure the work schedule. Wall mounted electrical cabinets will be installed immediately after finishing the first coat of water-based paint.

Grounding wire for electrical panels are carried out from the position of installation to the main distribution cabinet to the position of earthed pile. Grounding piles will be carried out immediately after leveling the floor. After completing the number of piles in accordance with the design, soil resistance measurements will take place. If the resistance does not meet the design requirements, Galaxy M&E will proceed to add an earthing ground until that will measure soil resistance. When the earthing system is completed, the electrical box and equipment will be put in place according to the design so that they can be installed and connected.

All electrical equipment after installation will be connected by Galaxy M&E via the intelligent building control system BMS

2.4. Installation of electrical equipment

Before installing electrical equipment, Galaxy M&E will use the equipment and technical operations to check parameters and quality before being delivered to the project. This is to ensure the project operates smoothly and conveniently for all of the investors which avoids time-consumption causing delays in construction progress.

Devices such as lights, switches and sockets are installed after pulling the wire and finishing the last layer of paint. The position of lights are placed on the concrete floor is determined in the process of construction, concreting the technical floor. The recessed ceiling lights and concrete floor will be designed and processed to ensure the heat of the lamp when operating. Dimensions and details of the light fixture will be provided to the investor and supervised consultants before production.

The ends of the wires connected to the switch are peeled off, attached to the switch, socket and domino so that the part of the wire is plugged neatly in the wiring hole. This will prevent a short-circuit. The plucked wire section should not be short which will help prevent bad connections. Switches, sockets during installation are measured with nivo scales to ensure neatness.

When installing the wiring system and electrical equipment, Galaxy M&E always follows strict procedures, technical regulations, and always carefully checks the design drawings to ensure that the progress is being maintained. The positions of electrical boxes must be accurate in both position and height. The wires are always marked to distinguish easily, to avoid confusion.

During the installation of electrical equipment, Galaxy M&E always requires a team of workers not to damage or chip the wires protection shell. When fully installing electrical equipment, it is a requirement to conduct an electric shock test and to check the operation of the entire electricity system. If unsatisfactory, they must be re-checked thoroughly before the contractors hand over the works to the investors.

Testing is always assigned by Galaxy M&E to experienced electrical engineers.

2.5. Connection checking and inspection

The connection of inspection, pre-acceptance test, electrical connection, testing and operation are the last steps done to ensure the execution and installation is done correctly in the electrical system of the project. Despite its completeness, this is a job that requires meticulous maximum. Any errors in the process of checking and inspection can lead to material damage, even life for the user. Because of such importance, this job has always been assigned by Galaxy M&E to the most experienced mechatronics engineers with the highest qualifications. The testing steps conducted by Galaxy M&E are as follows:

- First, proceed to press the first cable before installing into the connection point of the device. There is no need to use a terminal, if the connection point structure is of small capacity.

- Next, check the connection diagram, the voltage of the device from the catalog or on the equipment label before making the connection.

- Finally, label equipment codes for junction boxes, lights, air conditioners, fans, light levers and light poles to facilitate maintenance management later.

Above are 5 steps to conduct construction, installation of electrical works. The detailed content of the work will depend on the requirements of the investor, design documents, standards of TCVN and IEC. When carrying out construction, arising issues at the construction site and further request from the investor is unpredictable. Therefore, the experience of construction, installation and handling of problems during the M&E process is always a top priority for any electromechanical construction unit.

With many years of experience in consulting, designing, constructing and installing electromechanical systems, Galaxy M&E is confident that it will always be the initiator of new and quality values for construction works.

Galaxy M&E