Recommends 3 basic procedures to prevent electrical accidents

Most accidents suddenly happen in a short period of time (in seconds). Therefore, to minimize human damage, Galaxy M&E experts recommend the following 3 basic factors.

Many electrical accidents have sad consequences. Mild injuries can cause skin burns, which can be permanent injuries leading to death. Most accidents suddenly happen in a short time (in seconds). Therefore, to minimize human damage, Galaxy M&E experts recommend the following 3 basic factors.

1. Preventing electrical accidents with wiring systems

1.1. Bare conductors

Electrical accidents due to bare conductors often occur due to violations of safety distancing between people and electrical wires. In addition to a safe distance, all conductive materials that people use or carry should also comply with regulations on height, and minimum safe distance from bare conductor wires. There have been many accidents due to workers transferring long steel bars which collide with wires; steel construction scaffolding installed too close to high voltage lines; crane equipment colliding with bare electrical wires leading to electric shock, death ...

Another type of an accident that may occur with bare conductors is caused by failing to ensure the minimum safe distance from the maximum point of the wire sag (the lowest point of the wire between two points) to the vehicles on the road. The overhead conducting line above the below traffic road must ensure a minimum height of 6 meters. In addition to ensuring height, there must be signs or signals to remind the maximum height of vehicles when in transit under bare conductors.

| Types of voltage | Voltage level | Minimum safe distance |

| Low voltage | Low voltage (<1kV) | 2 m |

| Medium voltage electricity |

Voltage from 1 kV to 20 kV Voltage from 20 kV đến 35 kV |

10 m 15 m |

| High voltage electricity |

Voltage from 35 kV to 110 kV Voltage > 110 kV |

20 m 25 m |

Non-sparking safety distance for conductors without using insulating materials| Galaxy M&E.

1.2. Underground cable

For underground electrical cables and insulated covers, accidents often occur due to excavators operating with conductors.

When making a plan of excavation, the boundary of the underground cable area must be demarcated. In many cases when excavating, electricity must be disconnected in cables to ensure absolute safety for people and equipment at the construction site.

Underground cables may also have broken insulation covers due to heavy mechanical equipment moving on the surface above the underground cables. This case is usually due to the previous work. The company which was in charge of constructing the cables did not comply with the minimum depth when burying the cables, and did not re-enforce the surface above the underground cable, leading to risks of electrical accidents. To limit these situations from happening, it is imperative that the underground cable construction company must bury the cable at a certain depth so that the pressure of vehicles moving on top of it does not cause the cable to stretch, crush or break the insulating cover. Cables under roads must be installed in steel or concrete pipes, with a diameter of at least 3 times greater than the diameter of cables.

2. Preventing electrical accidents caused by technical manipulations

One of the major causes of electrical accidents is human subjectivity. The reason for this is because workers are not fully equipped with safety knowledge when using and operating electrical equipment.

Lack of electrical knowledge can easily lead to occupational accidents.

In order to limit and eliminate the causes of electrical accidents, during the technical process, the following principles must be followed:

- Before participating in the operation of electrical equipment, especially in factories, industrial parks, export processing zones, workers must attend training courses about safe electrical operation. For specific types of equipment, it is necessary to have the guidance of electromechanical experts, equipment manufacturers, or distributors.

- Before repairing / installing / executing ... electrical equipment should be checked to see if they are all within safety regulations (working environment, air humidity, obstacles, conductor casing / equipment ...). Before operating make sure no one is using / coming into contact with electrical equipment or wires. Only connect the circuit when all conditions have been checked and ensured that it is safe.

- In the process of using and operating electrical equipment, workers must fully and properly use personal protective devices.

- When constructing / repairing overhead electrical equipment, it is imperative for workers to stand on a good support system and with insulating panels (wooden or rubber insulated). Also, workers must use safety belts, helmets, gloves, insulated protective shoes, protective clothing in accordance with the work performed. In addition, when operating from a high place, in stead of having one person directly doing the process of repairing / connecting / installing electrical equipment, there must be another person standing near by to support. Supporters also play a role of alerting and handling unforeseen situations that may occur during work.

- In factories, industrial parks, export processing zones, people without electrical engineering expertise are absolutely not allowed to get involved in the installation / repairing / operation of electromechanical equipment.

- In offices / residential areas, people without electrical expertise should not repair any electrical equipment / wires without the help of someone with electrical engineering expertise. In case of emergency, the entire power line should be disconnected before conducting , repairing or connecting.

3. Preventing electrical accidents in working environments

The environment is one of the two factors that imposes danger caused by electricity. To minimize the occurrence of electrical accidents, when operating electrical equipment in different environments, the following things should be paid close attention to:

- Wet environment: Must be fully equipped with protective gear, labor tools to ensure electrical insulation. Plus, prepare appropriate possible solutions for each type of wire / machinery / electromechanical equipment. In case personal equipment does not meet all the requirements of electrical safety for all body parts, it is absolutely forbidden to operate / repair electrical equipment.

- In dusty environments, especially metallic dust, with conductive materials: Conductors must be highly insulated. In each conduit containing wires, it is allowed to contain only one wire, not many electrical wires. All electrical equipment must be contained in insulated boxes sufficiently to ensure no flashover.

- In general working environment: Ground wires need to be installed which will take the current instead of the human body. In addition, when operating electrical equipment, workers should be fully equipped with labor protection to ensure insulation. When in contact with live metal parts, special tools with suitable insulation should be used.

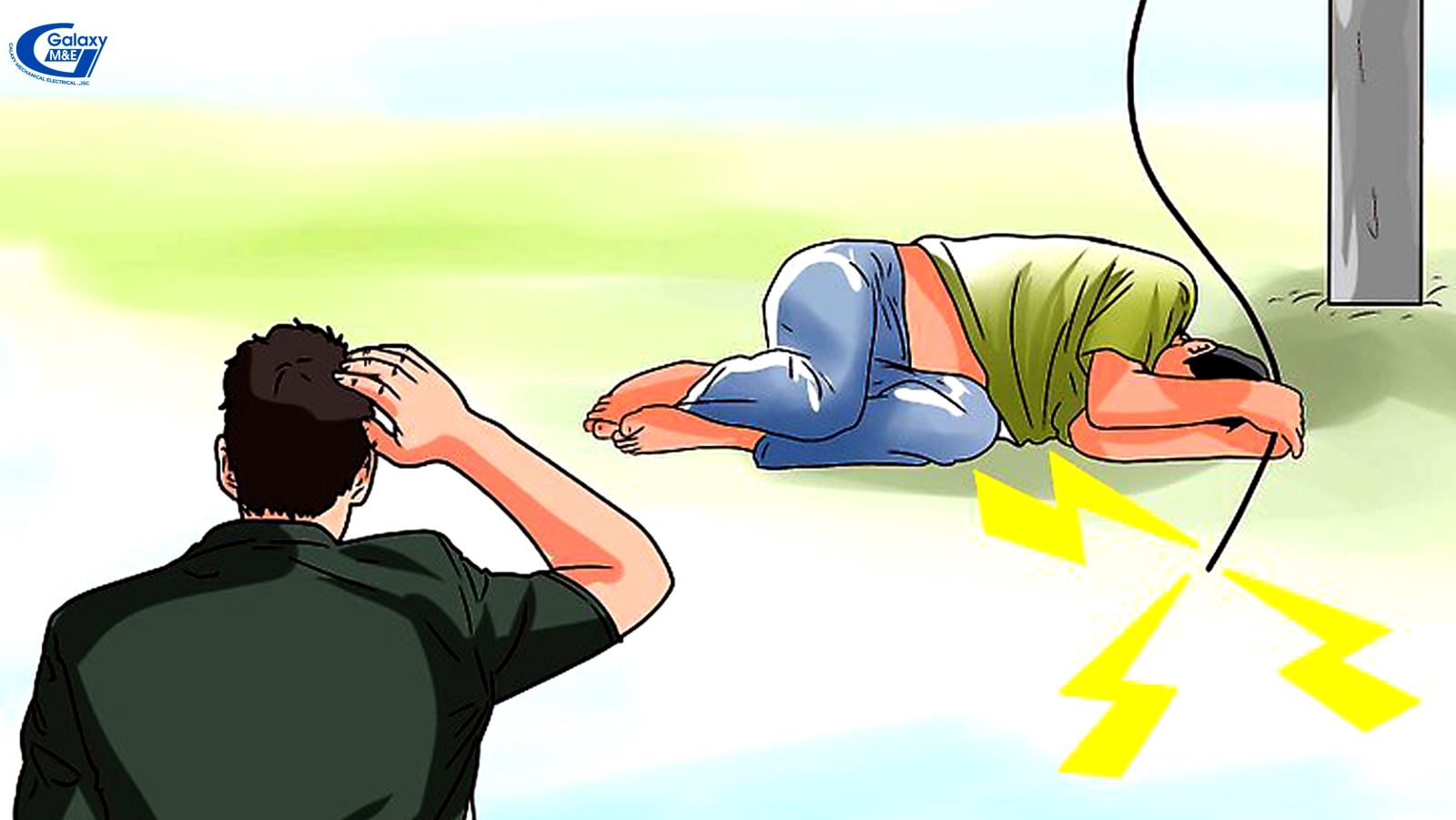

The electrical wires fall to the ground creating a deadly dange.

- In areas with step voltages: When detecting a broken conductor falling or exposed with the ground, immediately notify or ask the surrounding people for solutions, and separate people from the danger zone with a minimum distance of 20 m. If the person that detects the accident is in the danger area (< 20m), before informing people, she/he must jump using only one leg to get to the safety area, or have people around place insulated carpets, wooden planks to create a way to move out of the danger area.

Those are 3 basic factors to help prevent electrical accidents. In addition to the factors mentioned above, in order to guarantee safety for people and electrical equipment; production establishments, industrial parks and export processing zones must fully comply with the Electricity Law and State technical regulations and standards on Electrical Safety. In the event of an electrical accident, it is necessary to isolate the victim from the power source, then conduct first aid properly to minimize damage caused by electricity.