Ventilation system & characteristics of fans in m&e works

The following article will introduce the characteristics of the wind and the advantages as well as the disadvantages of the 8 types of ventilation fans currently used in common ventilation systems in factories, buildings and electrical and mechanical projects.

Since ancient times, people have known how to protect themselves by avoiding the strong sunlight, storms, etc thanks to the formation of a house. Enclosed structures such as walls, floors, and roofs make the indoor environment separate from the outside. However, the indoor environment is still influenced by some factors such as temperature, humidity, air flow rate. At the same time, the internal factors also negatively affect the atmosphere like people, electric devices. These factors produce heat, which raises the rooms temperature or releases toxic gases.

Equipping ventilation devices and air-conditioning systems is a necessity, especially for large projects with large concentration of people. Ventilation systems help circulate the air, increasing air flow to push the wind in the direction that benefits the user, during this process the system prevents and ventilates the toxic gas and dust from being released in a working or living environment.

With the purpose of taking the most of the natural advantages, effectively promoting mechanical and electrical equipment, and understanding the characteristics of wind will help improve the living and working environments air, therefor contributing to protect and preserve the ecosystem in general.

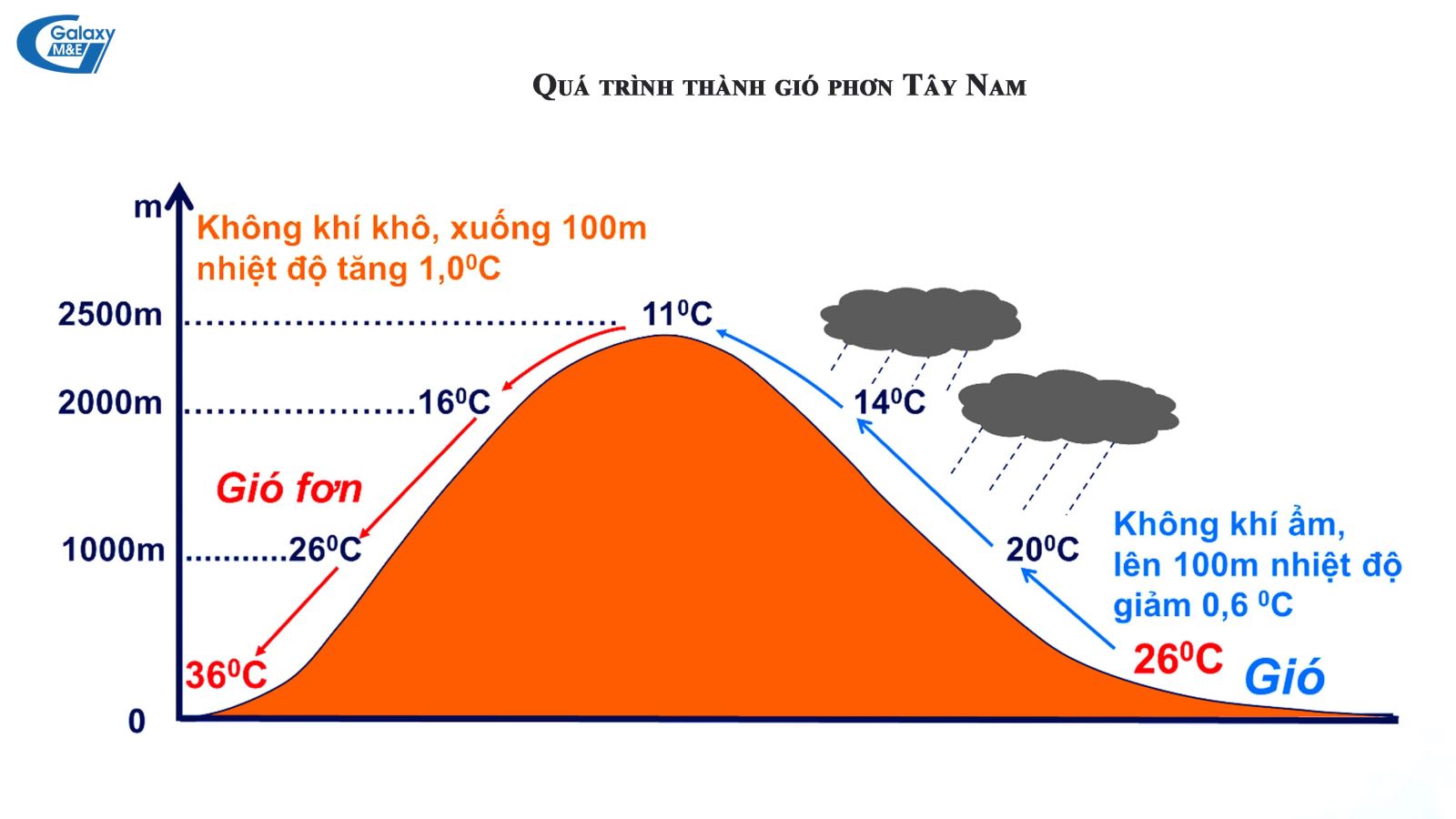

Southwest wind, also known as Lao wind, brings a relaxing atmosphere to the central provinces

of Vietnam.

Note:

| Quá trình hình thành gió Tây Nam | Southwest wind formation process |

| Không khí khô, xuống 100 m | Dry air, down to 100 m |

| Nhiệt độ tăng 1 độ C | The temperature increases by 1°C |

| Không khí ẩm lên 100 m | Humid air to 100 m |

| Nhiệt độ giảm 0.6 độ C | The temperature decreases by 0.6°C |

1. The impact of wind on our country

First, it is necessary to understand what wind is: The wind is the movement of air from a high pressure area to a low pressure area. 3 basic characteristics of the wind are: wind direction, wind speed, frequency of wind in all directions.

In winter, Vietnam is influenced by 2 factors:

- The tropical monsoon from Siberia (high pressure) brings cold air. The tropical air from the Eastern Sea is hot and humid, the combination of both the monsoon and the tropical eastern air create cold air. At the end of winter, in addition to cold air, there is also steam, creating a humid atmosphere for the Northern climate.

In summer, Vietnam is influenced by two main wind types:

- The first one is the Tropical air in the North Indian Ocean. Despite its cool and moist origin, due to the Foehn effect (Foehn is derived from the German language-föhn), after crossing the Truong Son mountain range, it forms Lao wind (southwestern winds) which is hot and dry.

- The second one is the Southern monsoon. It is cool and humid, bringing summer rain.

2. Ventilation system

Based on the land characteristics, our country often uses two main wind systems, namely natural ventilation and forced ventilation.

2.1. Natural ventilation

House architecture is one of the factors that helps the air circulation run harmoniously, stably, warmly in winter, and cool in the summer.

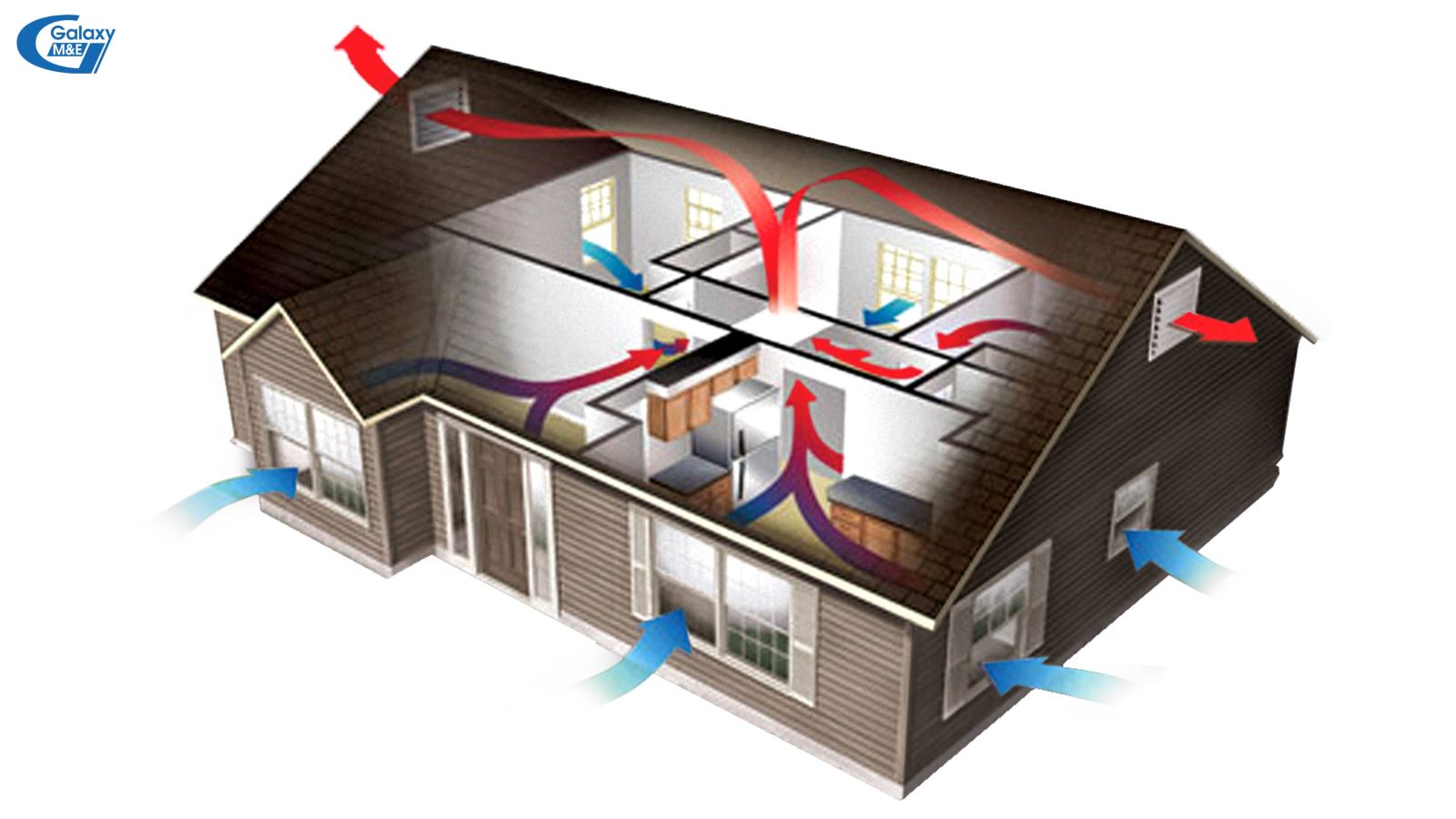

Natural ventilation is the use of physical attributes from architecture to take advantage of natural conditions to save energy, keep the temperature stable and create a cool atmosphere (like feng shui). Natural ventilation is done by creating ventilation corridors inside and outside the building. Through corridors (or skylights), the air current that forms the stream moves proportionately, causing hot wind to ascend, and cold wind to descend, then rise again.

Some methods of natural ventilation are: Using equipment (ventilated by windows, wind cotton) and some architectural solutions (organizing skylights, ventilation axes for houses; increasing the number of openings on doors, building courtyards and side walkways).

With the characteristics of the wind system which affect Vietnam mentioned above in Part 1, combined with folk experience, when the people in the north build their houses, they don’t choose the North side to place windows to avoid cold winds in the winter. Although some provinces such as: Nghe An to Thua Thien Hue are influenced by Lao winds, they should still make sure their homes and working environments are ventilated correctly either via natural ventilation or by physical architecture. Houses built in the south of Vietnam should have windows set to the south.

If the natural ventilation method fails, it is necessary to use forced ventilation.

2.2. Forced ventilation

Forced ventilation is a type of building ventilation system that uses fans or blowers to provide fresh air to rooms when the forces of air pressure and gravity are not enough to circulate air through a building. There are 3 methods of this: using exhausters, using blower fans, and using both of them.

3. Types of ventilation fans used in electromechanical works

Fans are the most common mean used to ventilate buildings.

3.1. Blower fans

The blower normally cools each small area in the house. This is a popular method because of its diversity, cheap price, low power consumption and suitable for small areas. This method uses table fans and ceiling fans to create ventilation. The advantage of the blower fan is to push hot air out of the area, which feels cooler, but the downside is that it only cools a narrow space.

Mist producing fans are one of the ventilation solutions used by many constructions.

3.2. Mist producing fans

The operation principle of a mist fan is that clean water is compressed with high pressure via a pump to create water pressure from 10 to 15kg / cm2. Through specially designed taps, it transforms water into ultra-thin molecules. The mist size is as small as 1/10 of the diameter of hair, diffused into the hot air by the blower which will create cool air. The mist absorbs heat thus reducing the ambient temperature by a difference of up to 7°C.

The advantage of a mist producing fan is to cool the air, and to condense suspended dust in the air to fall to the ground to make the air more fresh. Mist producing fans are often used in cafes, restaurants, resorts, factories, farms, greenhouses, stadiums, sports clubs, etc.

Besides the advantages, mist producing fans also have certain disadvantages. If the air compressor and water tank are not cleaned regularly, bacteria will start to grow. Through the misting system, bacteria has the opportunity to spread more into the environment. It is also one of the causes of respiratory diseases. In addition, the mist producing fan also makes the air moist for long periods of time, creating conditions to stimulate the growth of fungi. This especially affects people with weak immune systems, weak resistance like the elderly, and young children. Also, because of the humidity created, misting fans are not used in offices containing many electronic equipment.

Industrial exhaust fans have advantages such as power, effectively supporting the ventilation in factories and businesses.

3.3. Industrial exhaust fans

Exhaust fans are used in industrial environments with the main goal of it is to prevent toxic air, smoke, and fumes created from factories to linger around.

Industrial exhaust fans have 2 types: Axial and centrifugal fans. Axial fans focus on the air and smoke, while centrifugal fans focus on the dust because of the following reasons:

- Axial fans have few blades. When rotating the blades will come into direct contact with the environment, so the dust easily extinguish , which can create corrosion. The motor is set outside which is moved with courroie wire. When there is dust, the contact between the courroie wire and the poulie will be easily broken, interrupting the motion function. With the motor located on the inner shaft, when dust is on the copper or bearing coils it also can cause the motor to overheat and run unstable, reducing performance.

Centrifugal fans have a larger amount of blades, the motor moves indirectly with the courroie wire placed completely outside, so they can avoid dust.

It therefore withstands air with dust to a certain extent. Centrifugal fans have better compression characteristics than axial fans, so they are often used to create pressures (up to 100,000 Pa).

- Centrifugal fans have the characteristics of creating great pressure, spreading the wind far away. Therefore, they are often used for ventilation, air-conditioning in combination with AHU or FCU copper tubes. After that, the duct will then be used to spread air to rooms that need air conditioning.

3.4. Axial fans

Axial fans are characterized by high airflow, and have low pressure columns which are suitable for sucking or blowing air in pipes at short distances. Axial fans are usually installed in ventilation systems of textile plants or the basement of high buildings; and the dust collector for wood processing industries, etc.

Tubular axial fans are often used to ventilate coal mines, and traffic tunnels.

3.5. Tubular axial fans

This type of fan is usually attached to an air duct to absorb more air. The main function of this fan is for smoke extraction in fire-fighting systems.

Tubular exhaust fans usually have 2 speeds (2 pole motor 2900 rpm and 4 pole 1450 rpm). Under normal conditions, it is a ventilation system running at low speed, when there is a fire, the central control system will increase the speed to extract smoke out of the workshops or buildings.

Structure of ducted axial exhaust fans including reels and covers:

- Reels: including inclined wings, bent forward or straight wings to create great pressure to help push gas;

- Covers: Used to direct the airflow in two directions, which is blowing air in and out. This depends on the curvature of the blades. The gap between the reel and the cover must be as small as 1.5% of the blade length.

Belt driven axial fans create the largest air flow among the types of ventilation fans used for buildings.

3.5.1. Belt driven axial fans

This type transmits wind force through the courroie wire to the rotor shaft. The advantage of it is that it has high wind flow (15,000 - 95,000 m3 / hour), low noise. Also, it is easy to increase or decrease wind flow, and convenient for motor maintenance. It is often used to ventilate the mines, suction and exchange - creating convection air in the factory.

The disadvantage of this type is that it is often necessary to adjust and replace the courroie cord. The rotation speed of the motor will be greater than that of non-courroie type, so bearings are more damaged. Besides the disadvantages, the biggest advantage of this type is that it is cheaper than the one without the driven belt.

The airflow of the axial fans is only 1/5 of that of the belt driven type.

3.5.2. Axial fans

The characteristic of axial fans is that instead of transmitting force through the courroie wire, the motor will be mounted directly to the rotor shaft. This type of fan is often used in textile factories as air-conditioning systems, and large warehouses.

The disadvantage of axial fans is exactly the advantage of the axial type with belt transmission. With the wind speed of pushing away only 1/5 of the courroie wire, instead of using it to bring air into the coal mines, axial fans are only used for factories, small-scale air conditioning systems or cargo storage (where few people work).

Wall-mounted axial exhaust fans have the advantage of low noise levels.

3.5.3. Wall-mounted axial exhaust fans

This type of fan has the following characteristics:

- Large wing diameter which can be manufactured according to customer requirements;

- Blowing air flow approximates the axial type;

- Low noise level, low power consumption;

- Having a wing system that opens when the fan runs to prevent insects and rain;

- When arranging many fans together, it will avoid the inverse airflow from outside to other fans that do not run, reducing the possibility of air change.

Wall-mounted axial fans are suitable for large-scale factories and textile factories.

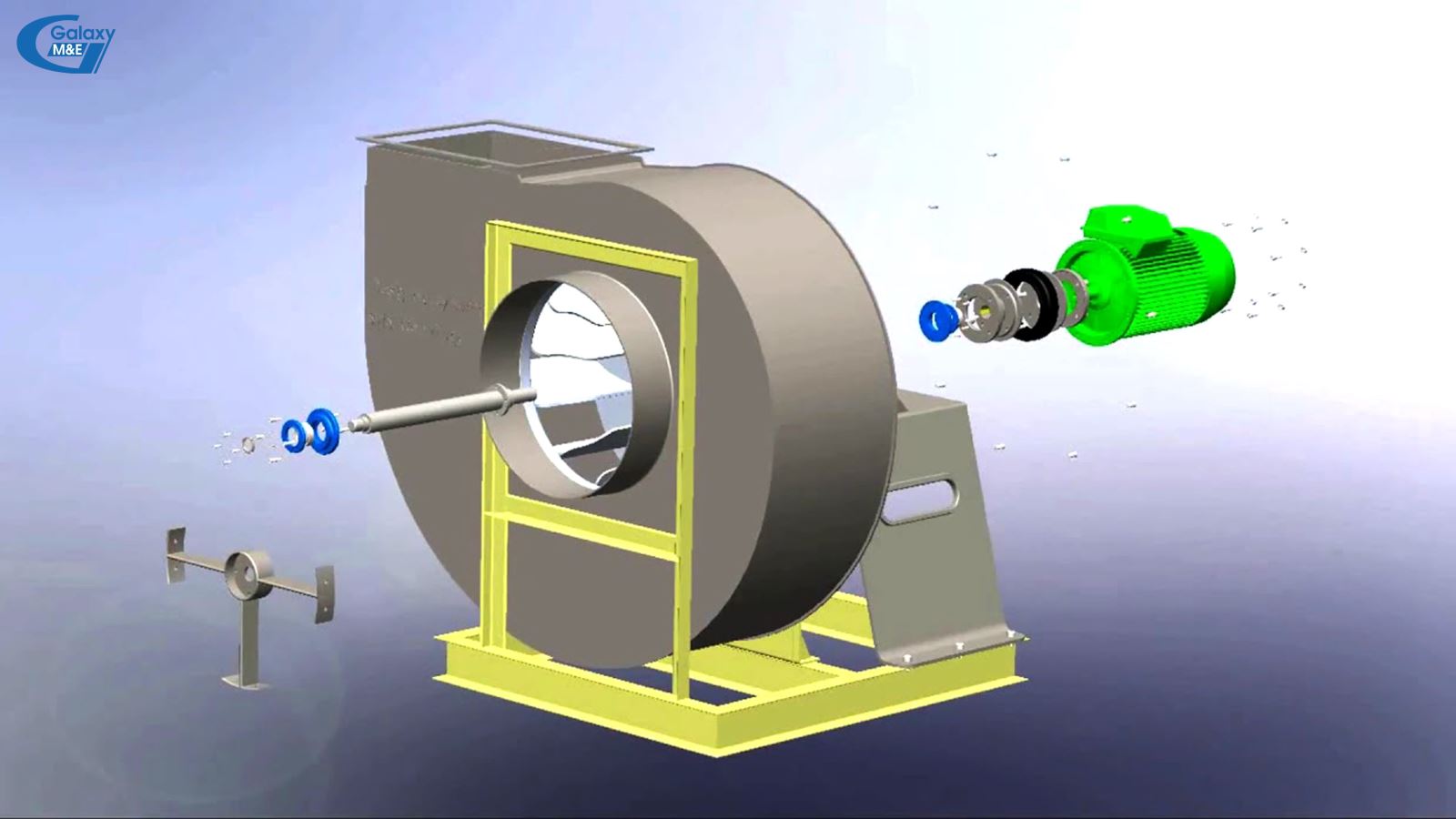

Centrifugal fans are often used for ventilation in rubber processing plants

3.6. Centrifugal fan

Characteristics of centrifugal fans:

- Air and wind are generated by operations that follow the principle of the centrifugal pump;

- Wind flow generated about 1,200 - 80,000 m3 / hour, lower and equal to approximately 1/2 of the wind generated by wall-mounted axial fans;

- Structure includes fan paddle (to create pressure and transfer air); fan case (focuses and diverts air flow); machine shaft, machine price;

- There are 2 types of centrifugal fans: Large ones have courroie wires (> 3 kW) and small ones do not use courroie wires (<3 kW).

Small centrifugal fans can be arranged indoors, large ones can be placed inside or outside of the house, thanks to the air duct system. The arrangement outside the house can reduce noise, absorb fresh air more easily.

Large centrifugal fans have motors mounted on racks, transmitting movement to the fans thanks to the belt. Fan speeds vary due to gear ratios of the belt and poulie systems. Centrifugal fans usually can not work independently without a duct system.

The effect of centrifugal fans is to exhaust and push pollution and toxic air; vacuuming in milling systems, rubber production, chemicals, wood workshops, etc.

With the characteristics of the mentioned types of fans, Galaxy M&E hopes to help customers gain more knowledge to make a choice that is more suitable to their needs and using the ventilation systems, effectively support the air conditioning system for the project, and better meet the needs of the investors as well as direct users.

Galaxy M&E